A Practical Guide to Smooth Label Ordering

Ordering labels doesn’t have to be complicated but preparation makes a big difference.

We often hear customers say: “What do I need to send you? What do you need from me?” and that’s exactly why we created this guide. It walks you through the key details that help us produce labels that arrive ready for your application, with no surprises.

Our goal is simple: produce high-quality labels quickly, accurately, and without unnecessary delays. The easiest way to achieve that is by receiving the right information at the very start.

Think of this as your practical checklist, everything that helps us deliver the best possible result for you.

Final Artwork (or Your Latest Version)

Providing print-ready artwork is the biggest time saver when ordering labels. Ideally, your file should include:

- High-resolution PDF artwork

- Correct label dimensions

- Bleed and safe zones

If your artwork isn’t final yet, don’t worry, just send what you have. We’ll review it and advise before production. We also have an in-house design studio that can work with you to refine or build your perfect design.

Why this matters: High-resolution PDF artwork allows us to position and adjust your design if needed while ensuring your labels print sharp and professional, without quality loss or delays.

Quantities & Label Variations

Let us know how many labels you need and how many versions are included in the order. We can quote you on a variety of quantities on the same quote, if you would also like to see the different price breaks.

For example:

- Total quantity required

- Number of label designs and how many of each version you need

- Whether designs share the same size, material, and finish

Remember – quantities don’t need to be split evenly if labels are produced in the same run.

Why this matters: Grouping compatible label versions into one production run reduces setup time and cost, saving you money and speeding up turnaround.

Material & Finish Requirements

Tell us what look and performance you want from your labels.

This might include:

- Matte, gloss, or textured finishes

- Specialty materials

- Durability needs

We’ll recommend options based on how your labels will be used.

Why this matters: Choosing the right material and finish ensures your labels perform properly and reflect the quality of your product.

What Your Label Is Being Applied To

Labels aren’t one-size-fits-all. The surface they’re applied to affects material and adhesive choice. Please let us know if your labels will go onto:

- Glass jars

- Plastic bottles

- Cardboard cartons

- Other packaging types

Why this matters: Matching the label to the surface prevents lifting or adhesion issues. It can also support recyclability – pairing compatible materials helps packaging move through the correct recycling stream.

The Conditions Your Label Needs

to Withstand

Tell us where your product will live. For example:

- Refrigerated or frozen storage

- Moisture or condensation

- Oils or frequent handling

Why this matters: The right material ensures labels stay intact and looking good in real-world conditions.

Accurate Label Size & Shape

Labels must fit your packaging perfectly. Please include:

- Width × height

- Shape (circle, rectangle, custom die-cut, etc.)

If you’re unsure, sending a sample container allows us to measure and recommend the best size. If size is not critical we can also suggest using one of our existing cutters where possible to save tooling costs.

Why this matters: Accurate sizing prevents production errors and ensures labels align and apply correctly.

Colour Matching Requirements

Tell us if your labels need to match specific brand colours, packaging, or previous print runs.

Why this matters: Early colour planning prevents mismatches, reprints, or delays, ensuring consistent branding.

Samples or References (If Available)

Existing labels, packaging, or visual references are always helpful.

Why this matters: Samples remove guesswork and reduce the chance of revisions.

Post-Print Overprinting

Let us know if you’ll be printing onto the labels after we supply them, such as batch numbers or dates. This might include:

- Thermal transfer printing

- Inkjet overprinting

Why this matters: Overprinting requires compatible materials to ensure proper ink adhesion and readability.

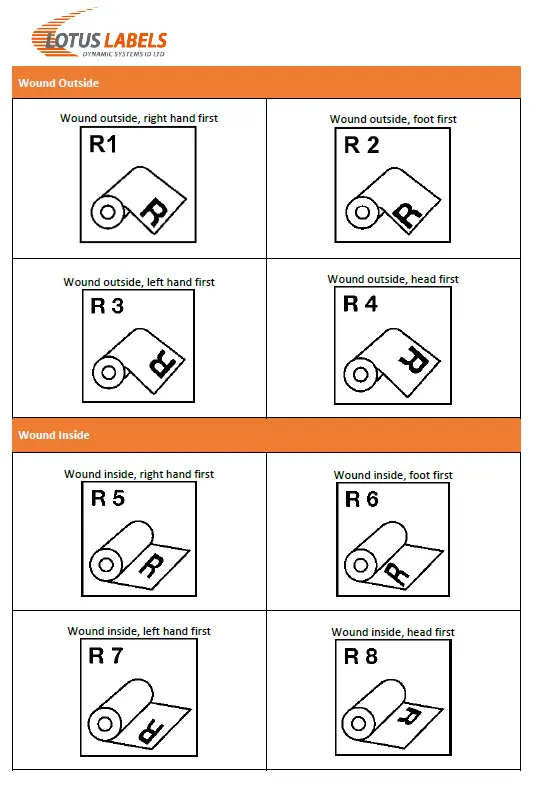

Tell us how your labels will be applied and their winding details.

Include:

- Hand or machine application

- Roll direction

- Core size (if applicable)

- Labels per roll, gap size between labels, alternating labels and max outer diameter of the roll

- If you do know the applicator make and model, please let us know.

Why this matters: Incorrect orientation or roll setup can prevent labels feeding properly through applicators.

Why Every Detail Counts When Ordering Labels

Labels may seem simple, but small details, artwork quality, quantities, materials, sizing, and application all play a role in smooth production and reliable performance.

Providing this information when ordering labels help us reduce delays, avoid costly revisions, and deliver labels that work exactly as they should.

And if you’re unsure about anything, just ask, we are here to guide you every step of the way. Contact us today.